| |

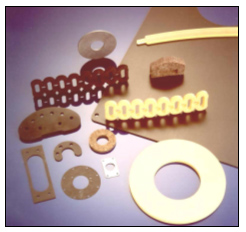

Electromagnetic Interference (EMI)/Radio Frequency

Interference (RMI) Shielding Products

|

|

Engineers designing electronic instruments many

times must manage electromagnetic interference (EMI)

that may cause an undesirable response, malfunctioning

or degradation in the performance of electrical

equipment. Electromagnetic interference (EMI)

shielding is the process of blocking the induction of

electromagnetic radiation, which is emitted by

electrical circuits carrying rapidly changing signals,

as a by-product of their normal operation to other

circuits which causes unwanted signals (interference

or noise). This is achieved by separating the circuits

with a barrier made of conductive material. One of

the best ways to protect from unwanted emissions is to

contain the noise within an enclosure. The enclosure

lid needs to make good contact with the enclosure

itself to create a complete conductive path.

|

|

J.J. Short Associates, Inc. has

several materials available to be custom molded or die

cut into EMI shielding shapes and gaskets. As with our

other product lines, J.J. Short Associates, Inc.

offers custom designed, EMI-Shielded O-rings, seals

gaskets and molded sheet stock for a variety of

electronic applications from prototype to production,

in small lots or long runs. Our EMI shielded O-rings

and seals provide moisture/pressure sealing and

EMI/EMP shielding when compressed in a properly

designed groove. They are interchangeable with

standard non-conductive seals of the same dimensions

or designed to meet your exact specifications and

dimensions.

J.J. Short Associates, Inc. offers conductive

O-rings and seals utilizing commercial grade and

military grade shielding elastomers and can produce

EMI-Shielded seals and gaskets in an unlimited variety

of shapes and sizes.

There are many types of EMI shielding materials and

solutions available to the engineer. Conductive

elastomers are an extension of our rubber

capabilities. We can provide EMI parts and gaskets

that are compression molded, die cut, or water jet cut

from electrically conductive silicone rubber

compounds. The main advantage of EMI shielding

gaskets, seals and parts fabricated from conductive

elastomers is the combined benefit of environmental

sealing over a broad temperature range and EMI

shielding. This conductive material is typically

silicone rubber or fluorosilicone rubber with embedded

silver plated aluminum particles, silver plated glass

beads, silver plated copper particles, nickel-graphite

particles or conductive carbon.

|

|

Many of our line of conductive silicone elastomers are

designed around the Mil-DTL-83528C Specification.

A partial listing of our compounds include:

Custom Conductive Elastomers Mil-G-83528 Qualified and

Commercial Materials

Type A = Silver (Ag) coated Copper (Cu) in Silicone 65

Shore A

Type B = Silver (Ag) coated Aluminum (Al) in

Silicone 65 Shore A

Type C = Silver (Ag) coated Copper (Cu)

in Fluorosilicone 75 Shore A

Type D = Silver (Ag) coated

Aluminum (Al) in Fluorosilicone 70 Shore A

Type E = Silver

(Ag) in Silicone 65 Shore A

Type F = Silver (Ag) in

Fluorosilicone 75 Shore A

Type G = Silver (Ag) coated

Copper (Cu) in Silicone 80 Shore A

Type H = Silver (Ag) in

Silicone 80 Shore A

Type J = Silver (Ag) in Silicone 45

Shore A

Type K = Silver (Ag) coated Copper (Cu) in Silicone

85 Shore A

Type L = Silver (Ag) coated Nickel (Ni) in

Silicone 75 Shore A

Type M = Silver (Ag) coated Glass in

Silicone 65 Shore A

Nickel and Nickel coated Graphite (30

Shore A to 75 Shore A) in Silicone

Our conductive materials are used to produce shielding

gaskets, seals, condiuctive o-rings, sheets and molded shapes

for Military, Aerospace, electronics, and communications

applications. Our range of conductive elastomers has expanded

to include materials that are designed to balance requirements

for electrical conductivity and cost performance for the

commercial sector.

Some Common Questions Regarding Qualifying EMI/RFI

Shielding Material

- What is the max ohms/cm in terms of volume resistivity

do you need to achieve?

- What is the max ohms/cm in terms of surface

resistivity you need to achieve?

- What environment will this material be exposed to? Or

does this need to be a solvent resistant or

fluorosilcione?

- Does this material need to meet the Mil-Dtl-83528C QPL

spec? If yes what type or call out? (the specs go from

type A to type M)

- Are you looking for a semi conductive or static

dissipating material or is this a true EMI/RFI shielding

application?

- What thickness do you need and at what thickness

specification in terms of +/-

Contact us

with your sketches, drawings and specifications and we will

see if we can help!

If it's made from rubber,

contact us!

|

|